Coating, drying and calendering [1]. Slot die coating allows for the the promising simultaneous coating of multiple layers of different fluids.

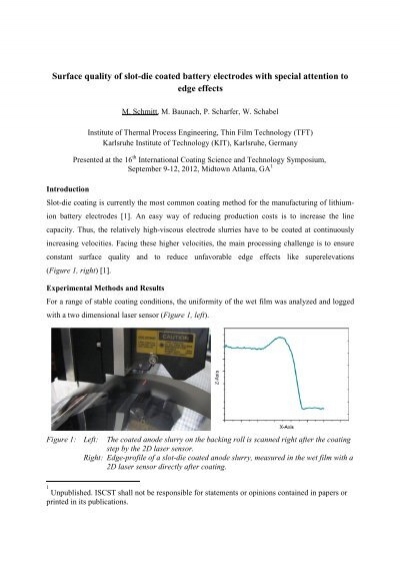

Surface Quality Of Slot-die Coated Battery Electrodes With Special

The scope of this work is therefore the scientific.

Slot die coating of lithium-ion battery electrodes. A phenomenon that is often neglected in scientific studies and has attracted little attention, compared to film. Increased line speeds and reduced scrap rates could help decrease these costs. Kit scientific publishing ist der wissenschaftsverlag des karlsruher instituts für technologie (kit) für qualitätsgeprüfte publikationen.

In the manufacturing chain, the electrode processing by slot die coating is one of the most crucial steps. Film casting (polyimide, urethane, epoxy, etc.) 2013 ) ( energiefachmagazin 4/13) multilayer slot die coating.

An easy way of reducing production costs is to increase the line capacity. The most frequently used coating method in industry is slot die coating. *free* shipping on qualifying offers.

Battery manufacturers are seeking to lower material In particular, novel and advanced cell stack formation processes cause challenging design requirements for electrode geometry. The advantages of subdivided electrode layers are diverse.

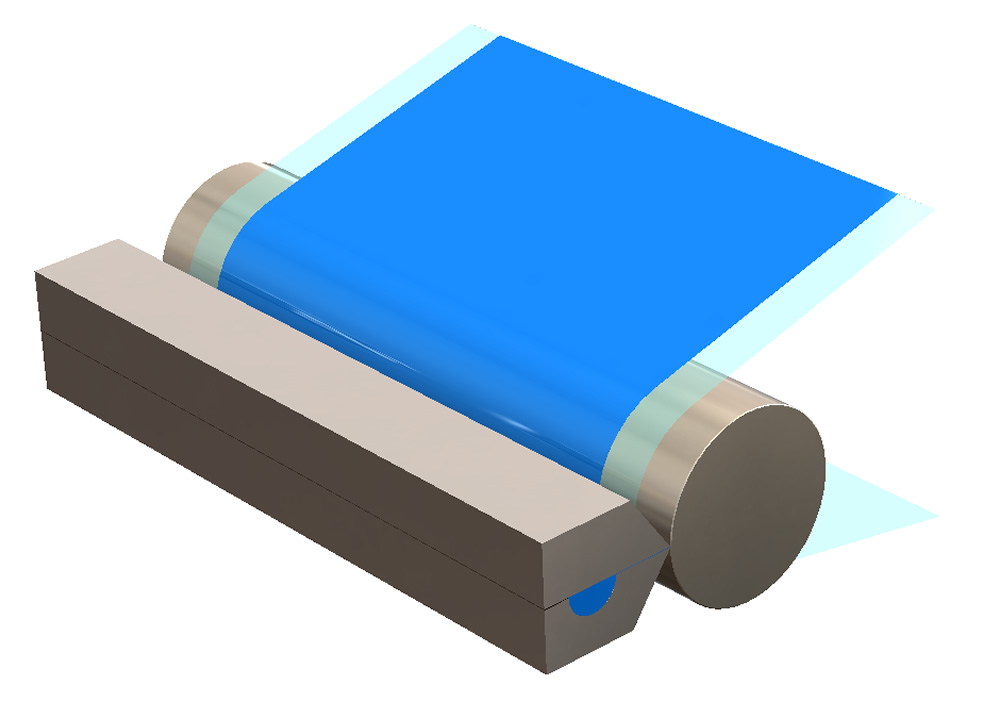

Engineering a smarter way to manufacture battery electrodes. Calendering allows higher energy and capacity densitiesin the final cell stack. A slot die with a backing roll only allows coating battery electrodes one side at a time.

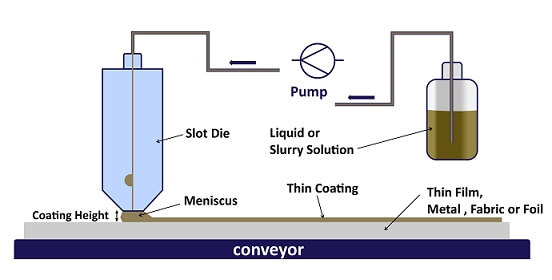

This process allows the reproducible preparation of thin functional films at high velocities. The slurry is applied on the first side by a slot die over a backing roller and becomes dry. Yasui seiki precision slot die is suitable for coating thicker layers with higher viscosity coating fluids.

Yasui seiki precision slot die is very useful when a coating method other than microgravure™ is necessary. Yasui seiki precision slot die is very useful when a coating method other than microgravure™ is necessary. Investigations on edge effect issues for stripe and pattern coatings.

Pdf Slot Die Coating Of Lithium-ion Battery Electrodes Investigations On Edge Effect Issues For Stripe And Pattern Coatings Semantic Scholar

Pdf Slot Die Coating Of Lithium-ion Battery Electrodes Investigations On Edge Effect Issues For Stripe And Pattern Coatings Semantic Scholar

Amazing Straightness With Only 048 Mm Deflection Over 1km Mitsubishi Materials Corporation

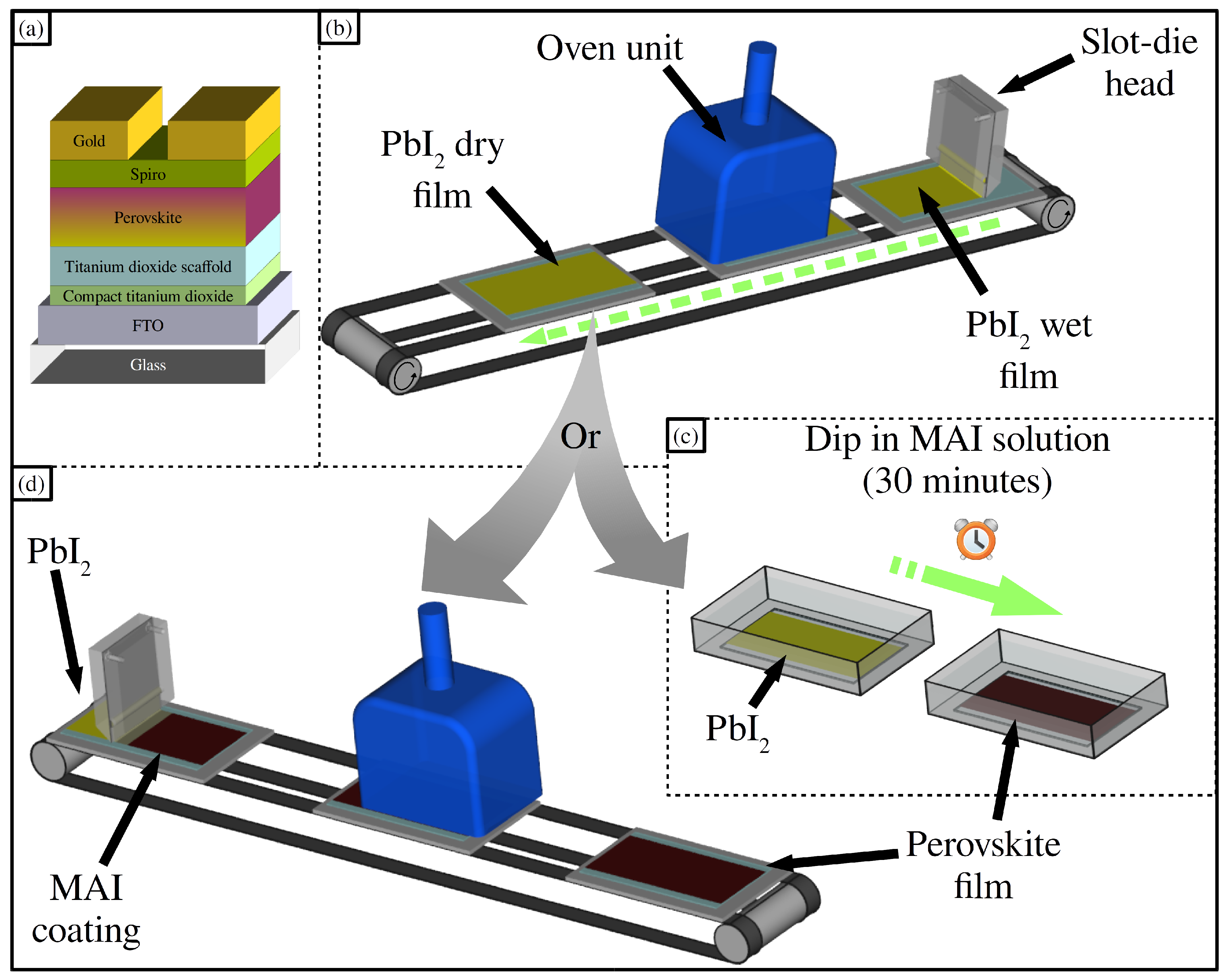

Materials Free Full-text Sequential Slot-die Deposition Of Perovskite Solar Cells Using Dimethylsulfoxide Lead Iodide Ink Html

Httpswwwenvironmental-expertcomfiles77download716854advancedbatteryelectrodemanufacturing-e301-2026pdf

Pdf Slot Die Coating Of Lithium-ion Battery Electrodes Investigations On Edge Effect Issues For Stripe And Pattern Coatings Semantic Scholar

Slot Die Coating Of Battery Slurry

Slot Die Coating Of Battery Slurry

E Scheme Of A Spray Coating B Tape Casting And C Slot-die Coating Download Scientific Diagram

Die Coater Technical Expertise Hirano Tecseed Co Ltd

Pdf Slot Die Coating Of Lithium-ion Battery Electrodes Investigations On Edge Effect Issues For Stripe And Pattern Coatings Semantic Scholar

Slot Die Coating Of Lithium-ion Battery Electrodes Schmitt Marcel 9781013283499 Amazoncom Books

Pdf Simultaneous Multilayer Coating Of Lithium-ion Battery Electrodes Semantic Scholar

Improvement Of Lithiumion Battery Performance By Twolayered Slotdie Coating Operation - Liu - 2017 - Energy Technology - Wiley Online Library

Improvement Of Lithiumion Battery Performance By Twolayered Slotdie Coating Operation - Liu - 2017 - Energy Technology - Wiley Online Library

Slot Die Coating Of Lithium-ion Battery Electrodes Schmitt Marcel 9781013283499 Amazoncom Books

Slot Die Coating Of Lithium-ion Battery Electrodes Schmitt Marcel 9783731504771 Amazoncom Books

Slot Die Coating - Yasui Seiki Inc

No comments:

Post a Comment